Nauta Conical Vacuum Dryer

The Nauta Conical Vacuum Dryer is a versatile, multi-purpose solution engineered for efficient processing across various industries. Known for its reliability, precision, and compliance with international standards, this equipment is a cornerstone in the manufacturing processes of chemicals, pharmaceuticals, food products, and more.

Nauta Conical Vacuum Dryer by Shiv Shakkti Process Equipment Pvt. Ltd.

Features of the Nauta Conical Vacuum Dryer

-

Multi-Processing Capability

-

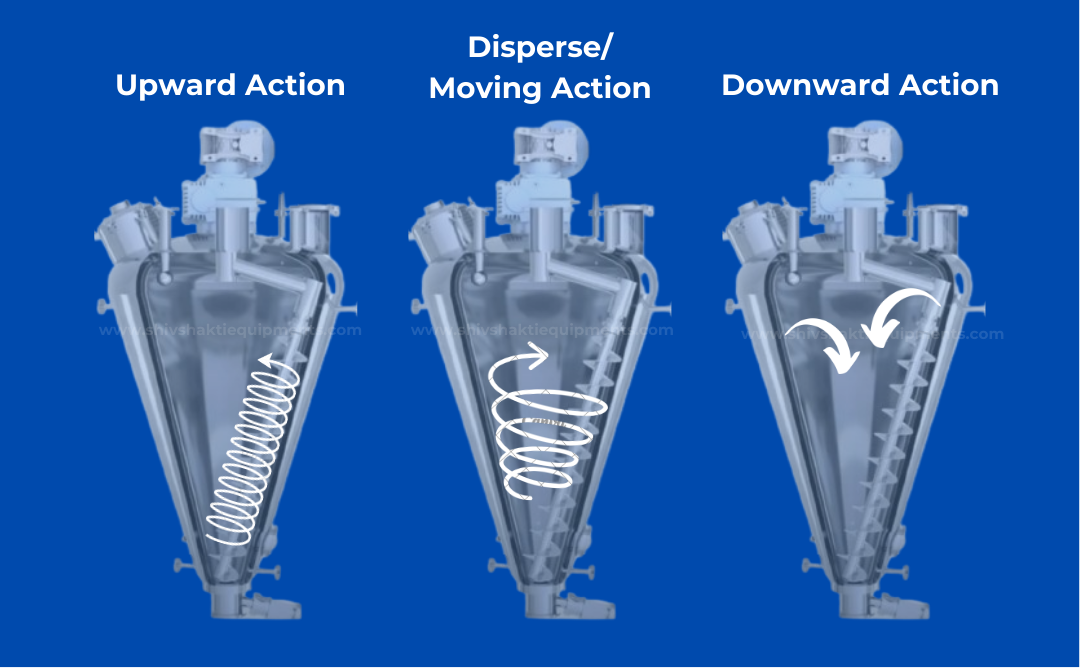

Capable of efficiently drying materials ranging from loose powders to heavy pastes and viscous liquids.

-

Enables a wide range of applications, including mixing, drying, cooling, crystallization, and more.

-

-

Batch Volume Flexibility

-

Offers batch volumes ranging from 5 to 22,000 liters, ensuring adaptability for various production scales.

-

-

Gentle Handling

-

No segregation or degradation of products, preserving the quality and integrity of sensitive materials.

-

-

Automated Cleaning Solutions

-

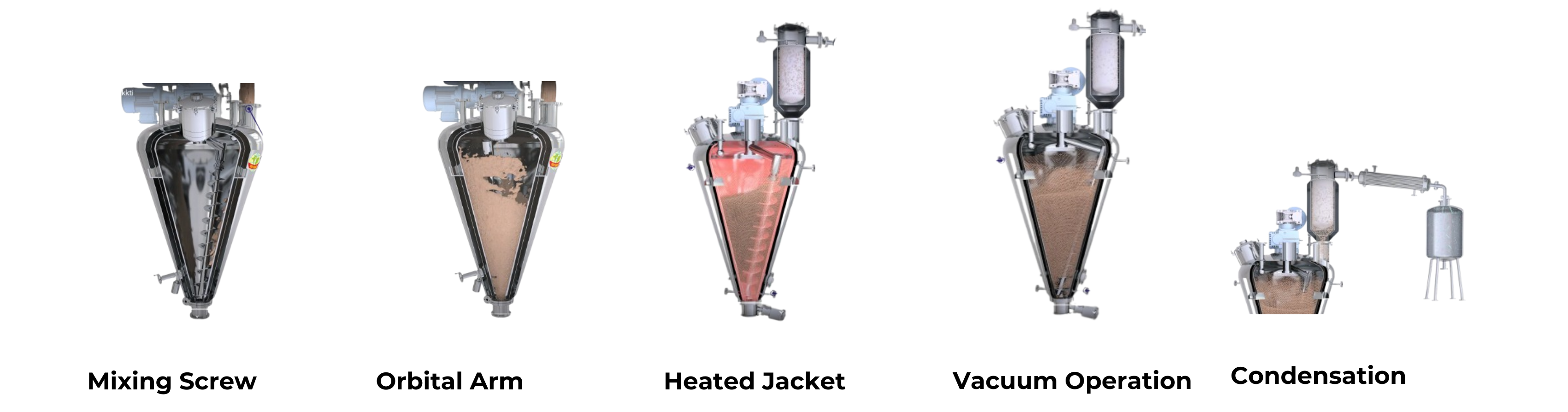

Equipped with patented CIP (Cleaning-In-Place) filters and skids for efficient and thorough cleaning.

-

Facilitates sterile processing with SIP (Sterilization-In-Place) features.

-

-

Interchangeable Auger Agitator

-

Available for dryers with capacities exceeding 20,000 liters, providing enhanced flexibility for large-scale operations.

-

Applications of the Nauta Conical Vacuum Dryer

- Mixing and Drying under Vacuum: Ideal for applications requiring precise moisture removal.

- Chemical Reactions: Supports alkalization and other solid-gas reactions.

- Cooling: Effective in reducing the temperature of solids and liquids.

- Crystallization: Facilitates controlled crystallization processes.

- De-aeration: Efficiently removes air from pastes and liquids.

- Sterilization: Ensures sterile product processing.

- Wet Agglomeration and Granulation: Handles solids with high efficiency.

Benefits of Combining Processes in One Vessel

Integrating multiple processes within a single vessel significantly reduces:

-

Investment Costs: Eliminates the need for multiple pieces of equipment.

-

Labor Requirements: Simplifies operational workflows.

-

Space Utilization: Optimizes factory layout by consolidating processes.

Optional Ancillary Equipment

To complement the Nauta Conical Vacuum Dryer, Shiv Shakkti Process Equipment Pvt. Ltd. offers:

-

Vacuum filters

-

Samplers

-

Heating/cooling skids

-

Ball segment valves

-

Lump breakers

-

Liquid injection systems

-

Control systems

-

CIP/SIP skids